When to use a trench rammer: A guide to compaction

On the job site, choosing the right tool makes all the difference. When it comes to soil compaction, you've got a couple of options: a trench rammer or a plate compactor. A lot of folks use them for similar jobs, but they're not the same.

So, when do you reach for a trench rammer instead of a plate compactor?

The difference between a trench rammer and a plate compactor

Plate compactors are better for larger, open areas. Think driveways, paths, or preparing a big site for a new building. They're good for sand, soil, and gravel.

A trench rammer, sometimes called a vibratory tamper or jumping jack, is a more specialised piece of gear. It's designed for tight spots and narrow spaces where a plate compactor won't fit. As the name suggests, it's perfect for trenches. It compacts a column of earth, getting a high level of compaction in a small area. This is crucial for things like foundations, footings, and around pipes.

Where you need a trench rammer

If you're working on a job that has a lot of obstacles or hard-to-reach areas, a trench rammer is your best mate. Here are a few places they excel:

- Trenches: This is their main purpose. For drain laying, cable laying, or pipework, a trench rammer compacts the soil back into the trench, ensuring the ground won't sink later on.

- Foundation piles and footings: To get a solid base for a building, you need to compact the soil deeply. Trench rammers can handle the kind of coarse material and stones you find in these areas.

- Landscaping: For smaller jobs or compacting around retaining walls, planters, and other tricky spots, a trench rammer is easier to manoeuvre than a larger plate compactor.

Choosing the right trench rammer

When you're looking at rammers, think about the impact force you need versus the machine's weight. The higher the force, the heavier the machine. For instance, a lighter model is ideal for compacting around pipes, while a heavier one is crucial for bigger jobs like foundation work.

For example, OMC stocks a range of German-engineered Weber MT trench rammers. The Weber MT SRV 300 is a lightweight option at 32kg, with a good impact force for smaller jobs. The Weber MT SRV 620 is over double the weight and offers a much higher impact force, suitable for prepping for foundation piles.

Why Wheel Kits Make a Difference for Trench Rammers

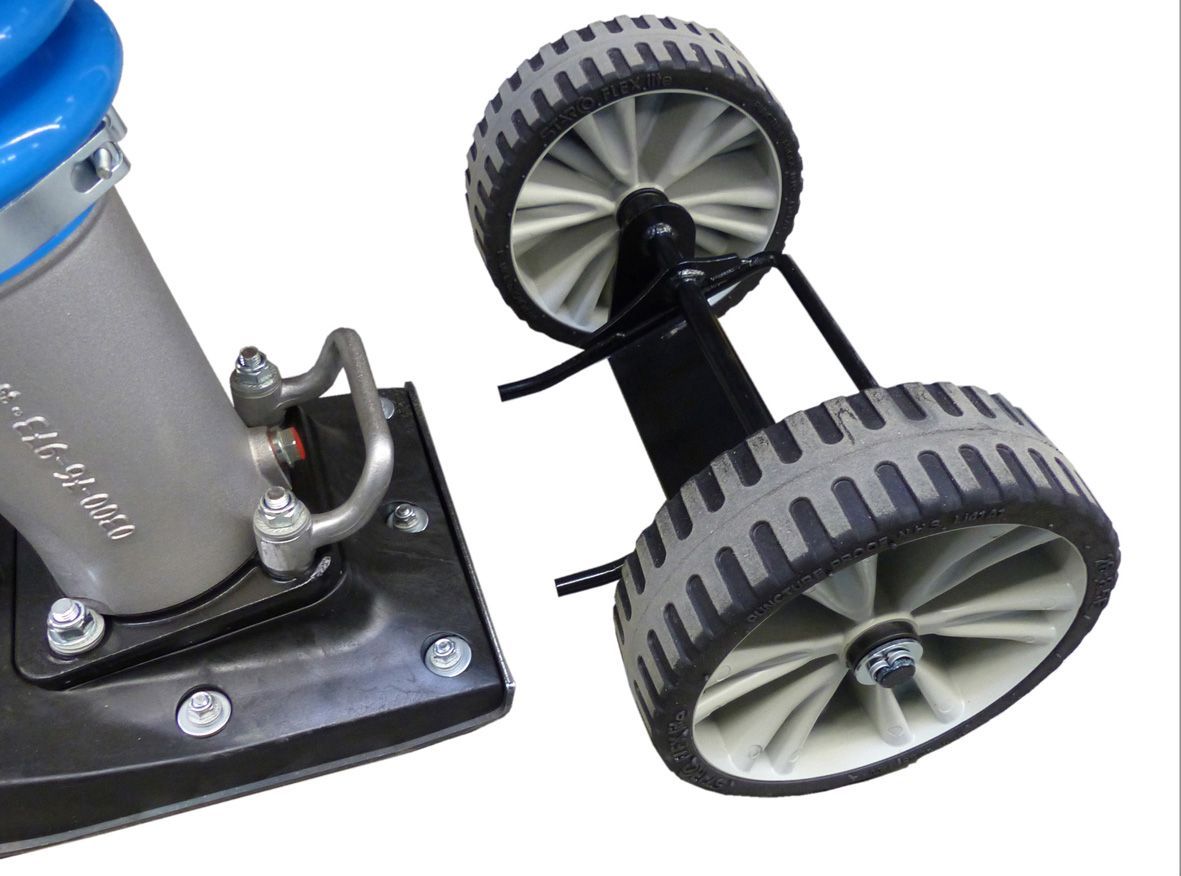

Wheel kits are a good accessory for trench rammers. They simplify machine movement on site. Operators can roll the rammer easily instead of carrying or dragging it.

This approach has two clear benefits:

- Reduces operator fatigue. Less physical strain on the person using the tool.

- Protects the machine. Rolling prevents damage from dragging, which helps extend the rammer's working life.

Wheel kits save time and protect your investment. They are a practical add-on for regular trench rammer use.

A few tips for using a trench rammer

- Check the soil: Make sure the soil is at the right moisture level. If it's too wet or too dry, you won't get a good result.

- Do your prep: Clear the area of debris and big stones before you start.

- Take your time: Don't rush. Guide the machine over the area and make sure each pass slightly overlaps the last one. The machine does the work; you're just steering it.

- Safety first: Always wear the right gear. Safety boots, eye protection, gloves, and ear protection are essential.

Need a hand finding the right gear for the job?

We're here to help. Get in touch with the team at OMC Power Equipment to talk through your project. We'll make sure you've got the right rammer for the job.